- Salt water kits are available at the time of pump purchase and are required for when operating with salt water.

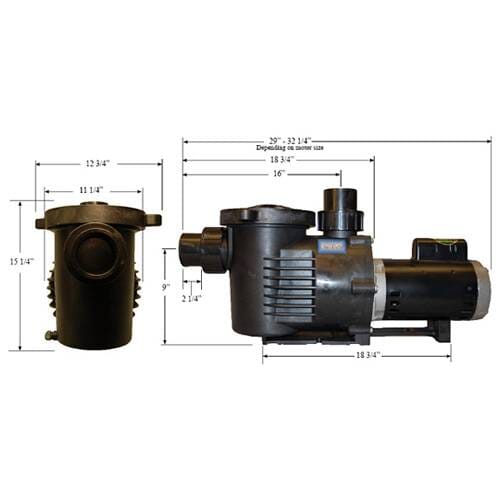

PerformancePro 1/3 HP ArtesianPro Low RPM Pump 7,320 GPH - 3" Fittings

✓ Questions? Call us (862)-362-1444

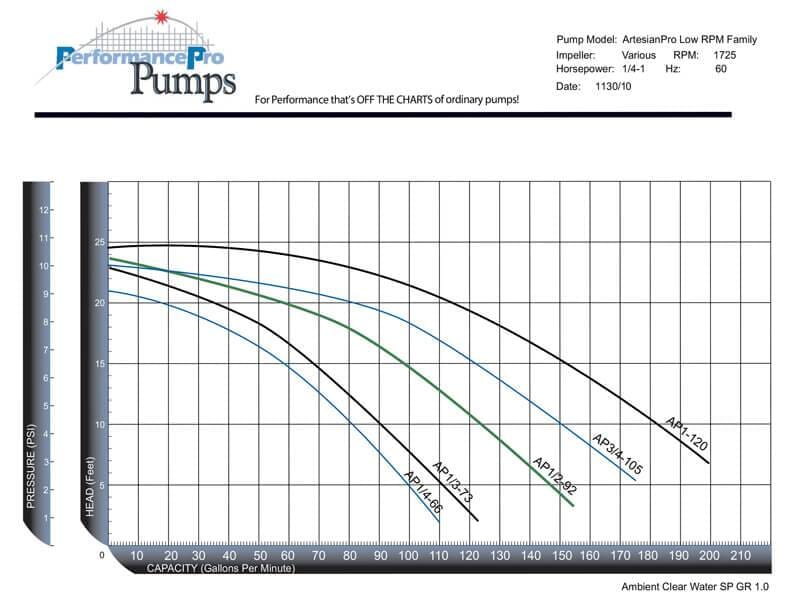

The PerformancePro ArtesianPro Low RPM pump is engineered for high-flow applications requiring efficiency and reliability. Perfect for larger pond setups, these pumps provide excellent flow rates at usable heads while ensuring energy savings and low maintenance.

Key Features:

- 1725 RPM Enclosed Motor: Fully enclosed, fan-cooled motor design for prolonged service life.

- Energy Efficient: High-efficiency pump and motor units help save on energy costs.

- Corrosion-Resistant Build: Equipped with durable stainless steel shaft seals to withstand various water conditions.

- Quick Connect Ports: 3" suction and discharge ports with options for 2" or 3" fittings for easy installation.

- Quiet Operation: Designed for noise reduction, ensuring a quiet, efficient system.

Additional Benefits:

- Impeller Interchangeability: Easily adjust the pump’s performance by switching impellers.

- Reliable Power Options: Operates at 115V with a 10 TEFC motor for dependable performance.

- Warranty: Backed by a 3-year manufacturer’s warranty for peace of mind.

The ArtesianPro Low RPM pump is a powerful, user-friendly solution for high-flow applications, providing durability and consistent efficiency.

Shipping Details

We at Aquascape Eco offer multiple shipping options at checkout for your convenience. All orders over $200+ are eligible for free shipping. Once your order has been Fullfilled and shipped (within 1-2 business days), you will receive a tracking number via email.

If your order does not arrive within the estimated shipping timeframe please contact our support team immediately at support@aquascapeeco.com or call us at 1.862.362.1444 for assistance.

Your satisfaction is our top priority at Aquascape Eco.

Important Delivery Notes;

ALL PERFORMANCE PRO PUMPS ARE BENCH TESTED AND SHIPPED DIRECT FROM PERFORMANCE PRO - Hillsboro, OR. THIS WAY YOU RECEIVE A WORKING PUMP WHEN YOU ORDER. PLEASE ALLOW AN ADDITIONAL 1-3 DAYS FOR PERFORMANCE PRO TO ASSEMBLE AND BENCH TEST YOUR PUMP ON TOP OF THE TRANSIT TIME.